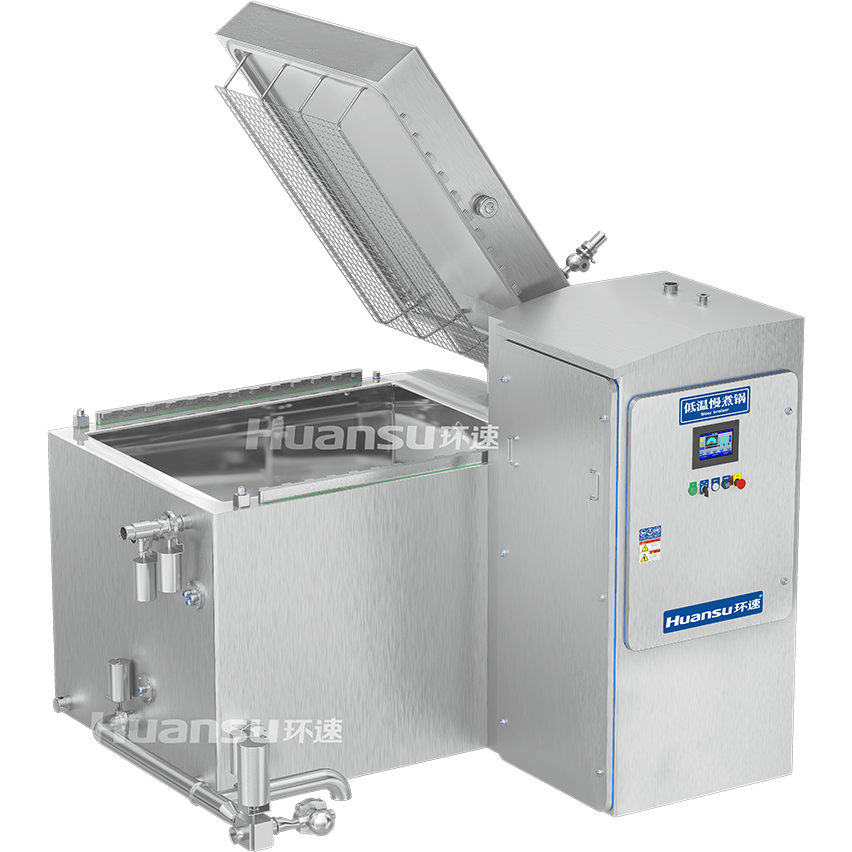

Efficiency & Quality

Large-capacity inner liner, three-dimensional heating, special hangers for batch feeding, guaranteeing high efficiency and large capacity. Advanced sensors measure temperature in real time to ensure process precision and achieve standardised production.

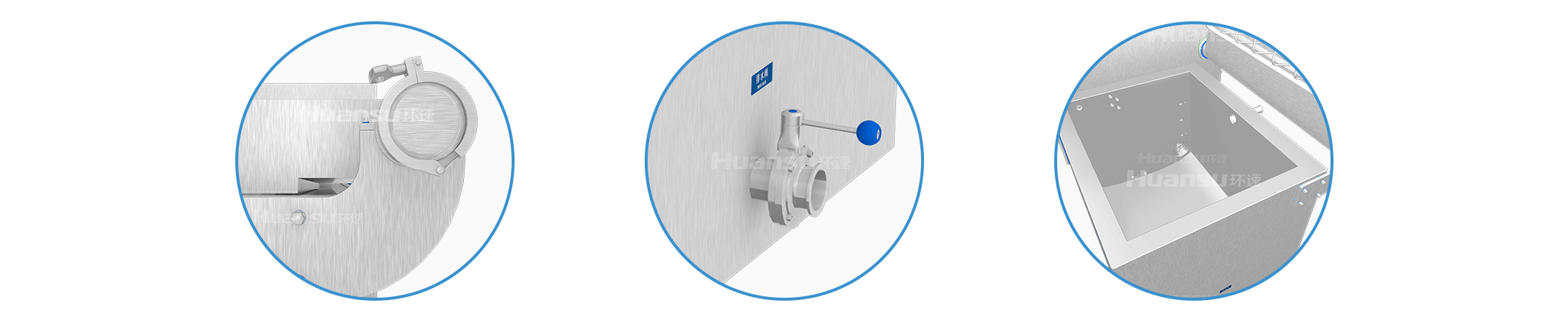

Hygiene & bacteria reduction

The equipment adopts sanitary fasteners, rubber seals and other measures to ensure smooth surface transition without gaps, eliminating microbial breeding; hangers and baskets can be directly steam sterilised in the pot to avoid cross-contamination; operation is concentrated in the intelligent terminal, reducing the potential for human-machine contact with the potential for contamination hazards.

Energy Saving & Consumption Reduction

Mechanized mass production, no need for manual involvement, reducing labor costs. Square pot design, high space utilization. Temperature control system regulates the steam flow according to the actual temperature, avoiding waste of resources. The pot body is filled with high thermal insulating material as heat preservation layer to reduce heat loss.

Easy cleaning

The protection level of the equipment is IP69K, and it can be directly washed by high-pressure water, chemical cleaning and steam cleaning. The inner liner adopts mirror polishing process and smooth transition design, which is not easy to leave stains and easy for daily cleaning. The equipment does not produce pollution in the process, easy to control the workshop hygiene.

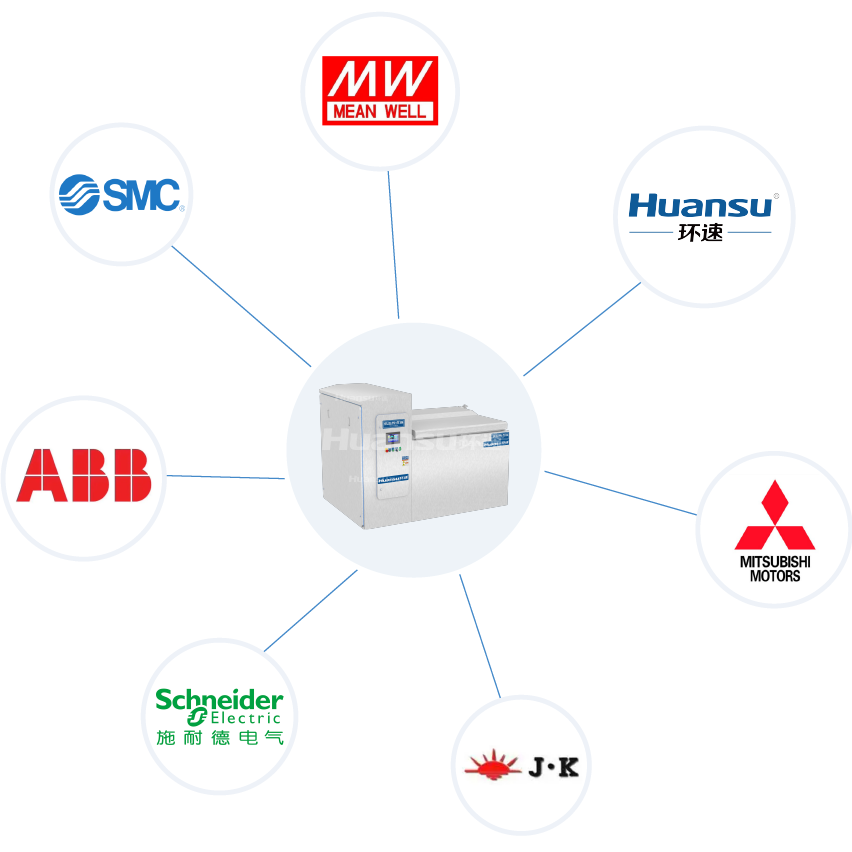

Stability & Security

The equipment has excellent material selection, fine workmanship, stable function and long service life. Electrical parts from international famous brand manufacturers, high configuration, good performance; electronic control cabinet waterproof and moisture-proof, to protect the safety of electricity; PLC encapsulated in the cabinet, anti-electromagnetic interference, to ensure stable operation.

Intelligent manufacturing

e focus on user experience, equipment compatibility and functional development. Users can operate the equipment through the touch screen, and the color screen intuitively displays the core parameters, making it easy to monitor the production process. The interface is simple and easy to use, which reduces the learning cost. The system can store historical process recipes for easy recall at any time. The program is modular design, can upgrade the firmware or add new functions as needed, convenient for the equipment to be embedded in the automated production line.