Automation

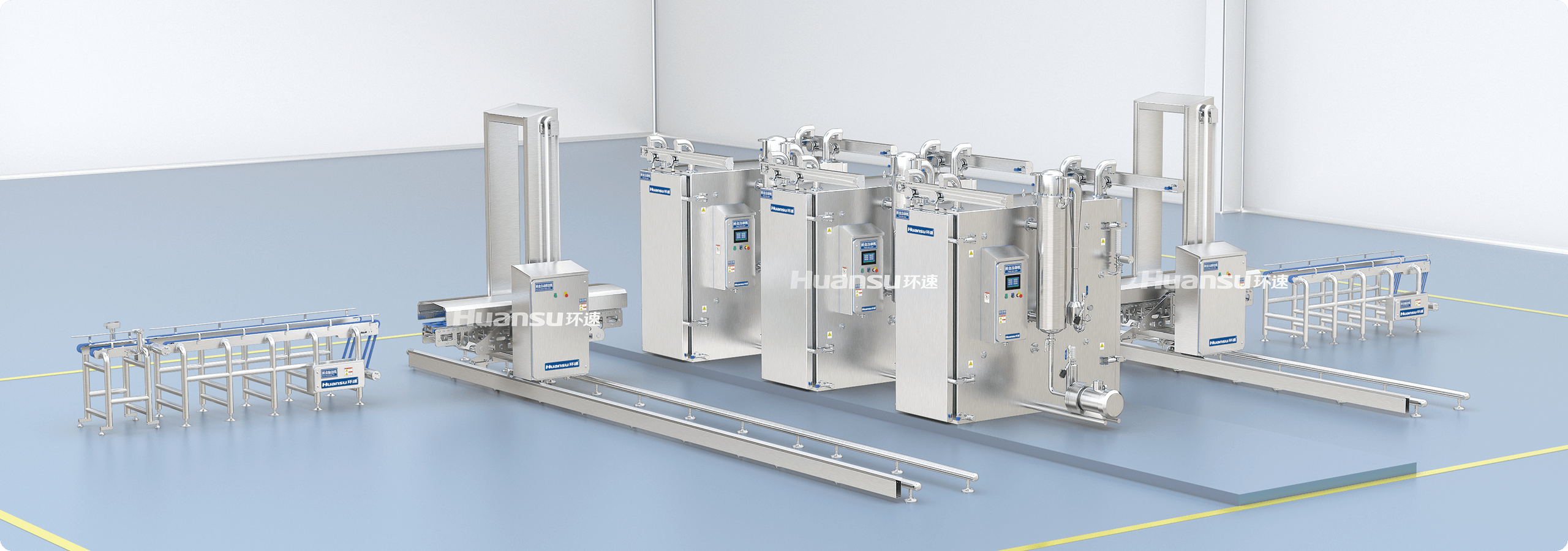

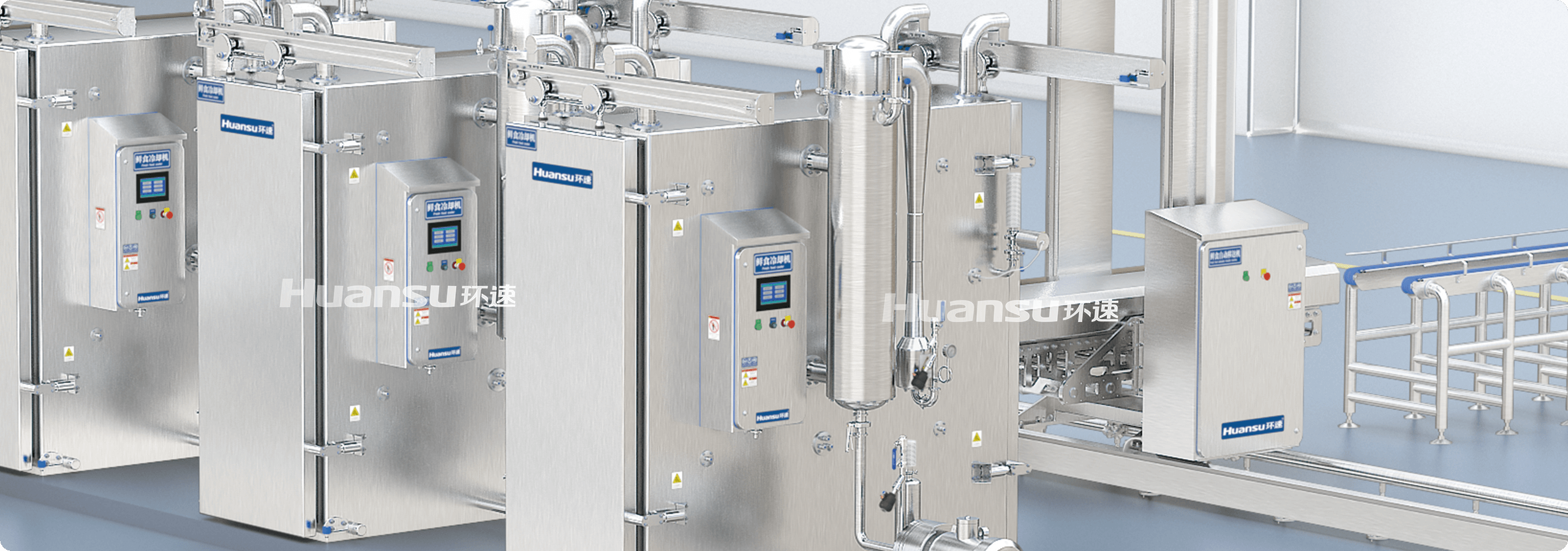

The production process is automated, with transportation, loading, cooling, and unloading of food strictly following the procedures without human intervention. A touchscreen with a graphical interface allows for real-time monitoring of process parameters, effectively simplifying operational steps. The system supports memory and export of historical process recipes for convenient and quick recall.

Efficiency & Quality

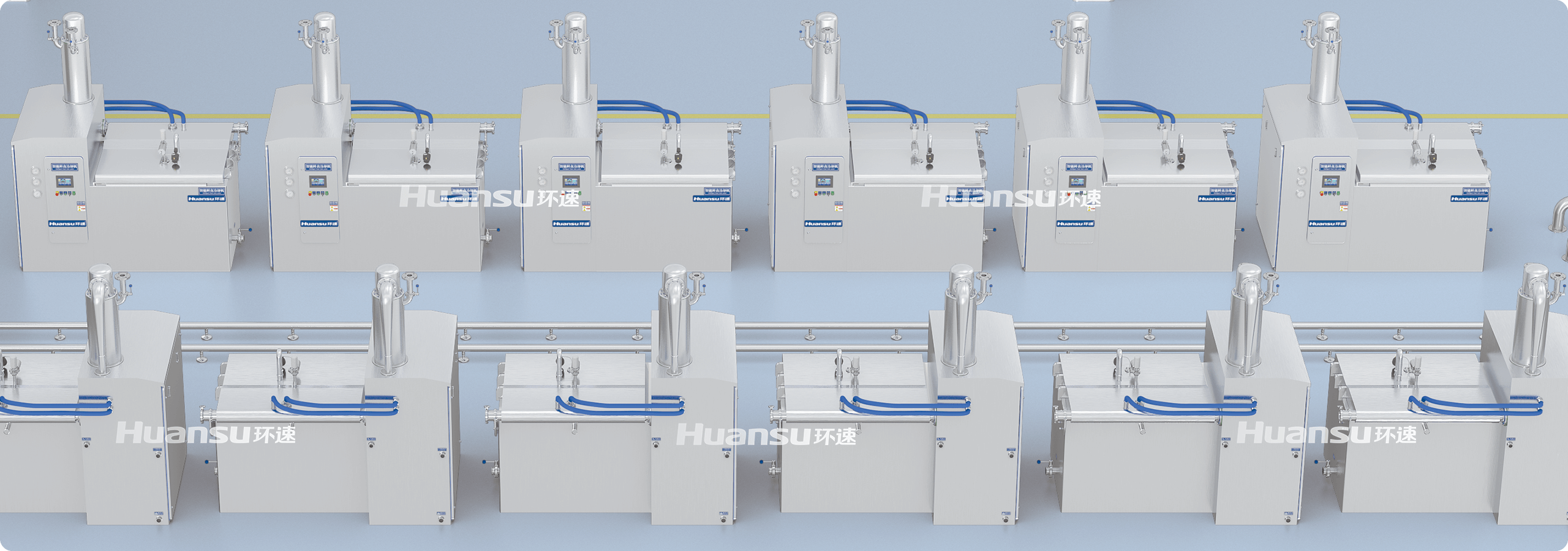

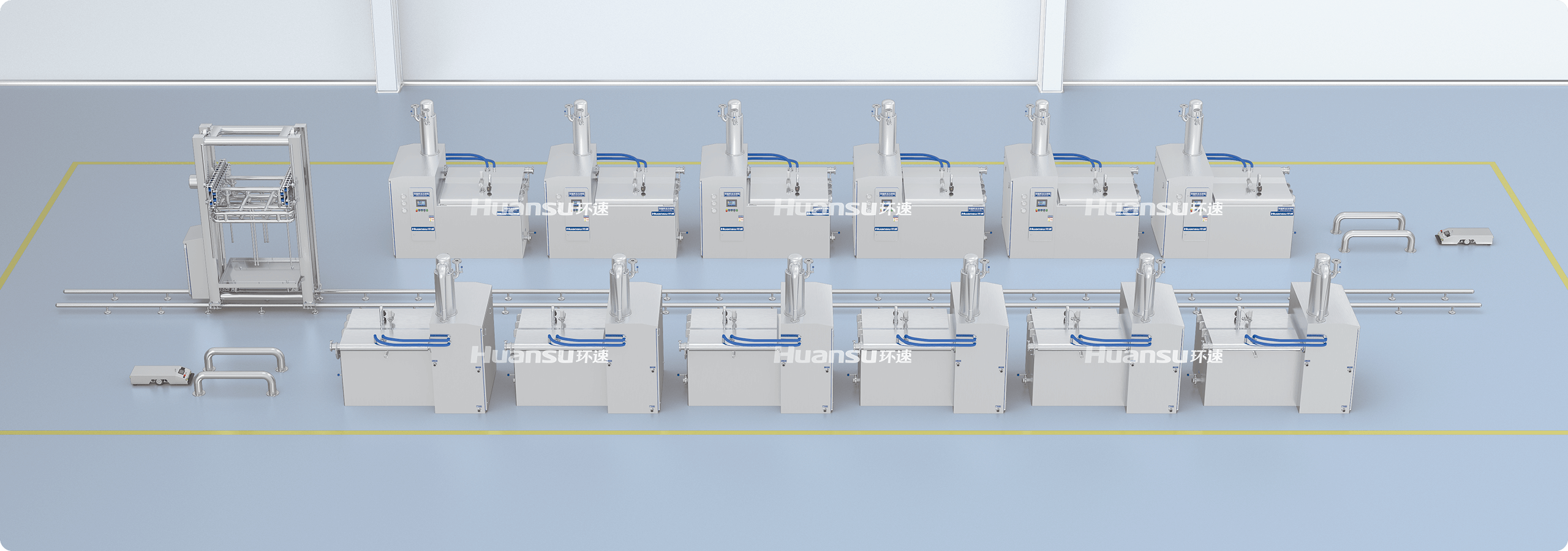

Customized intelligent scheduling algorithms and programs ensure seamless integration of each process, allowing multiple cooling machines to operate simultaneously for high-efficiency large-scale production. The innovative vacuum rapid cooling technology cools food quickly and uniformly, reducing temperatures from hot to ambient in just 3-10 minutes (depending on the type of food). During cooling, the food is in a sterile and oxygen-free vacuum environment, which can prevent external contamination, inhibit bacterial growth, and extend the freshness period.

Hygienic & Antimicrobial

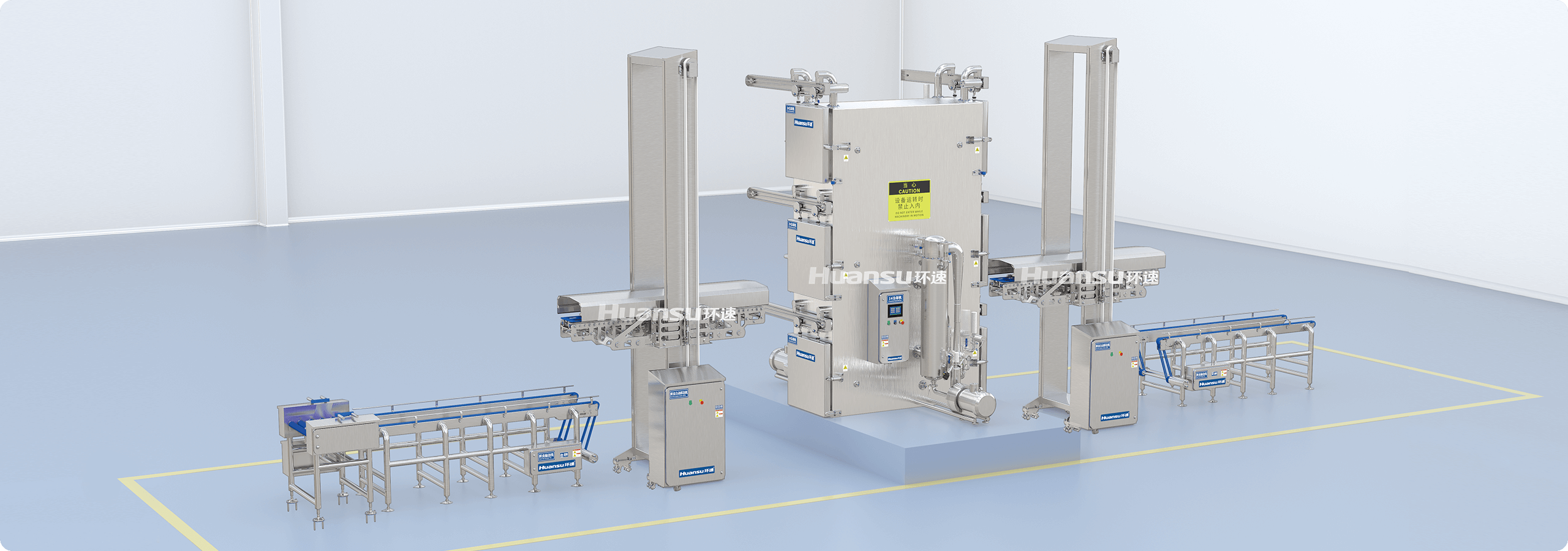

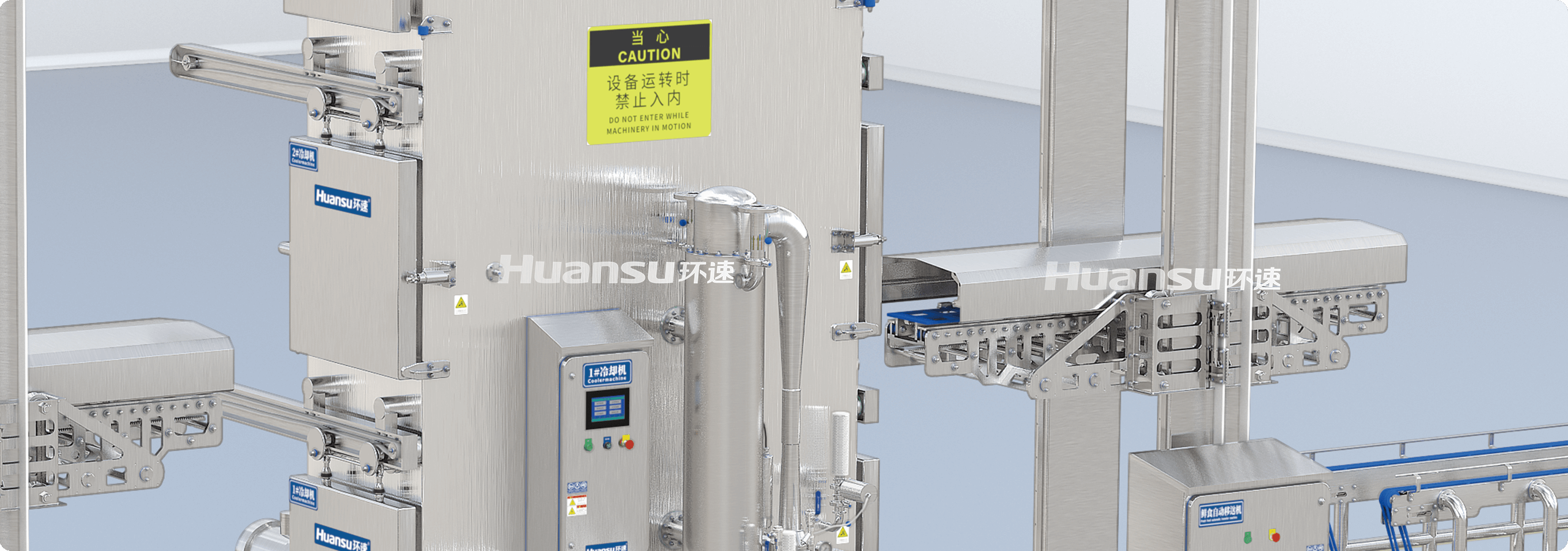

The production line's protective rating meets IP69K, capable of withstanding high-pressure water washing, chemical cleaning, and steam cleaning, significantly simplifying daily cleaning and maintenance tasks. Multiple measures are adopted to ensure the equipment surface is smooth without dead corners, preventing dirt accumulation. The top-opening cooling machine is equipped with CIP nozzles on its lid for easy cleaning of the inner chamber.

Energy Efficient & Low Consumption

The production process is fully automated, saving on labor costs; the equipment design is simple and the layout compact, saving space in the workshop; all cooling chambers use double-layer insulation design, effectively conserving energy. The production line can adopt a workshop layout with separate cold and hot zones, implementing hygiene grading control to reduce workshop renovation and daily cleaning costs.

Stability & Security

Food-grade materials, hygienic design, and medical-grade processes ensure a long product lifespan and high safety factors. Electrical components from international brand manufacturers are stable and reliable in performance. The electrical control box is waterproof and moisture-proof, ensuring safe electricity usage. PLC shielding against electromagnetic interference ensures stable operation.

Intelligent manufacturing

The production line solution integrates cutting-edge technologies and advanced concepts such as IP69K, environmental friendliness, and Industrial IoT, incorporating innovative achievements from fields like intelligent control and mechanical automation. It possesses good scene compatibility and functional extensibility, fully meeting your company's current productivity needs while maintaining its advanced nature through functional upgrades, effectively ensuring your company's technical leadership advantage in the industry.